HIGH ALUMINA Refractory Fire Brick

33.0 INR/Piece

Minimum Order Quantity : 1000 Number

Delivery Time : 2 Days

Call us now

07971550145

Minimum Order Quantity : 1000 Number

Delivery Time : 2 Days

Water Absorption Low porosity for maximum heat efficiency

Warranty Yes

Usage & Applications Boilers, Furnaces, Kilns, Chimneys, Incinerators

Usage Industrial

Types of Refractories Monolithic Refractory

Thermal Conductivity 30%, 40%, 50%, 60%, 70% (Available) Calorie (IT)/second/centimeter/°C

Surface Finish OK

Strength High

Specific Gravity 30%, 40%, 50%, 60%, 70% (Available)

Size Customized

Shape Brick

Purity(%) 70%

Product Type Refractories

Porosity 30%, 40%, 50%, 60%, 70% (Available)

Melting Point FURNACE

Material Stainless Steel

Hardness (%) Low porosity for maximum heat efficiency

Form SOLID

Density 2.0 2.3 g/cm Kilogram per cubic meter (kg/m3)

Condition New

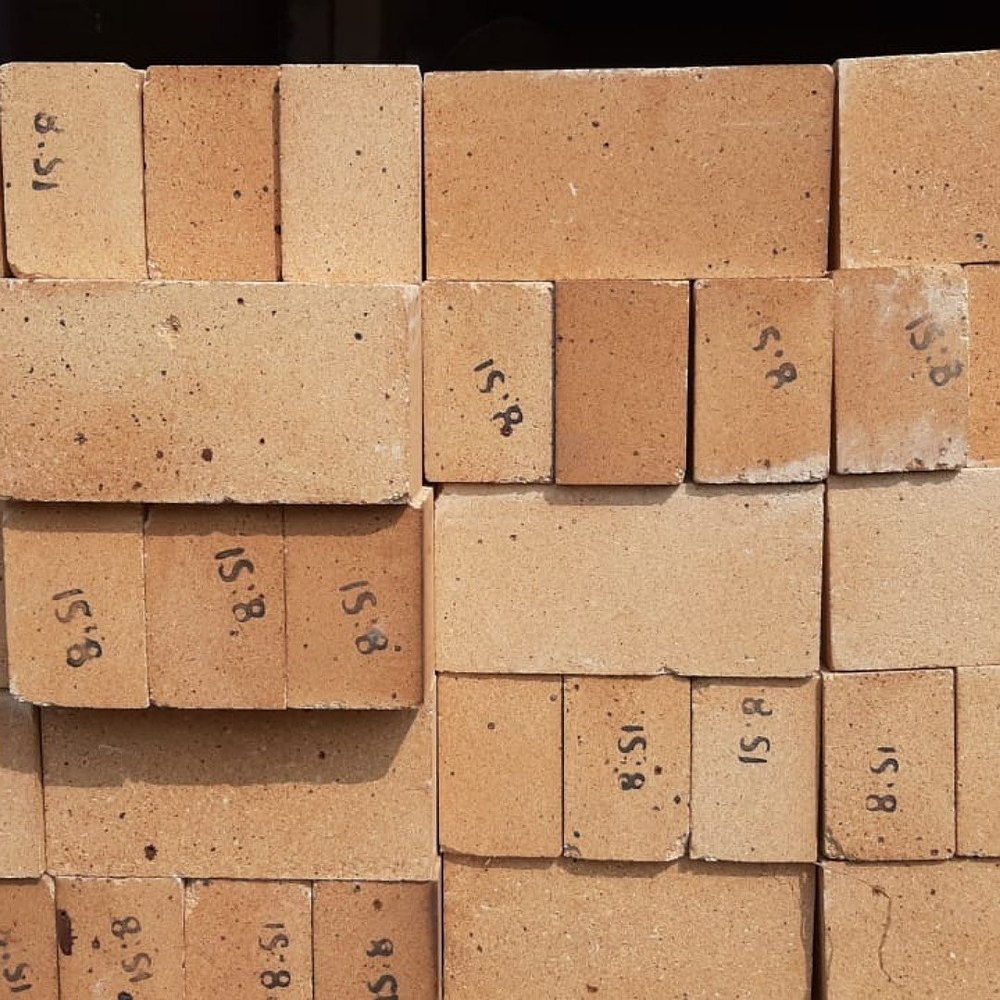

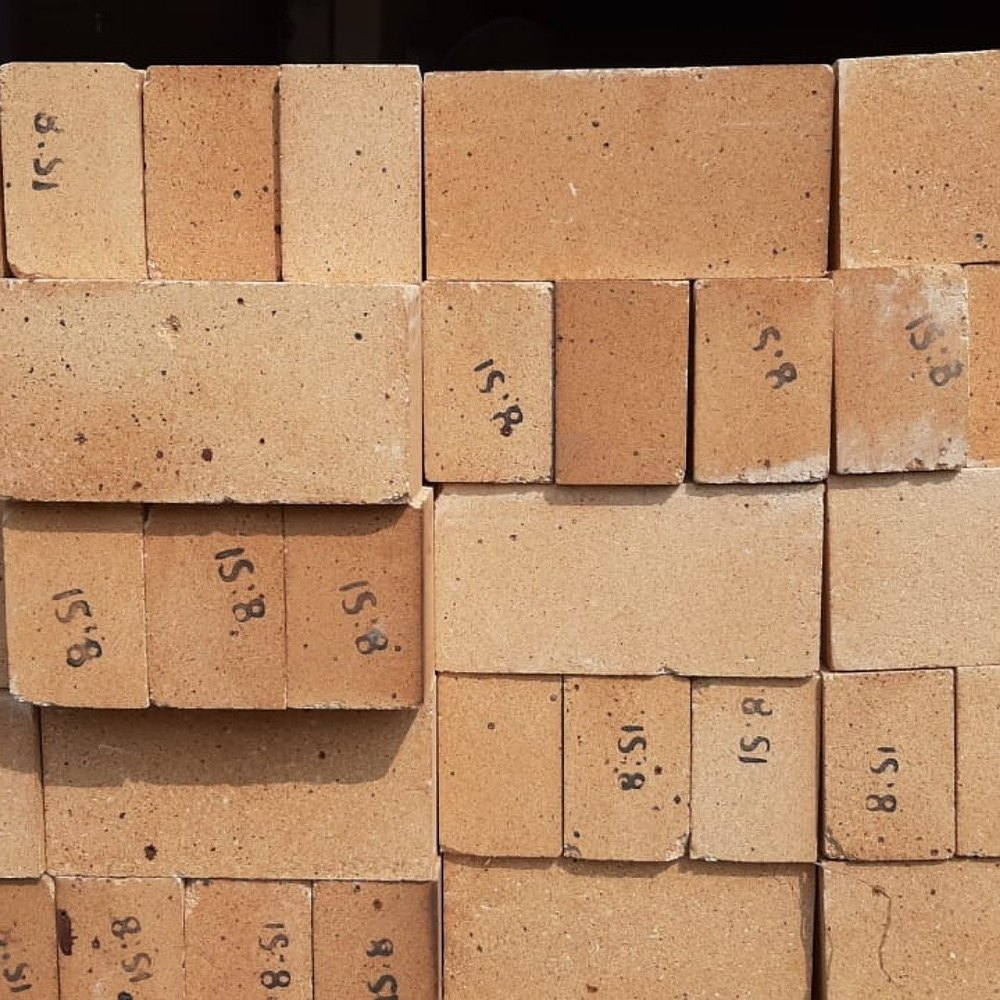

Color Brown

Chemical Composition 30%, 40%, 50%, 60%, 70% (Available)

Application Industrial

Supply Ability 100 Per Month

Main Domestic Market All India

Delivery Time 2 Days

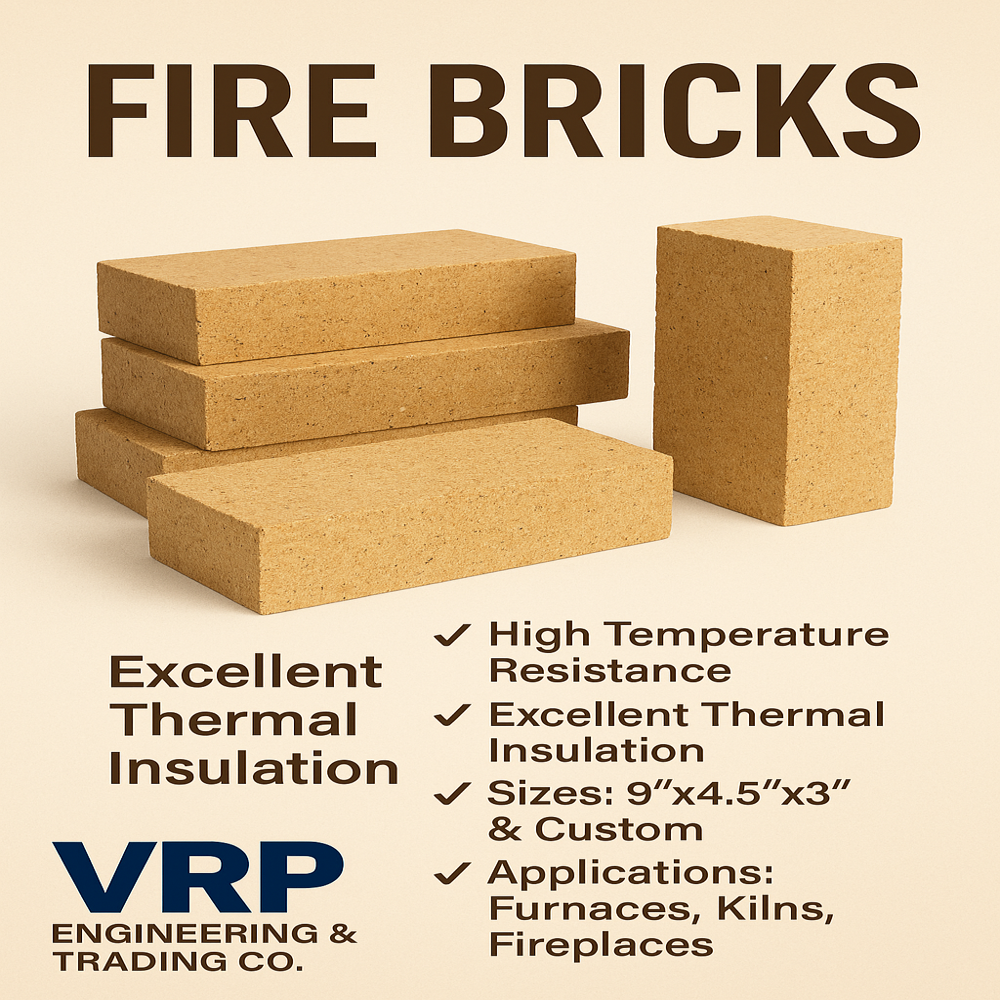

High Alumina Brick, Insulation Brick High-quality Refractory Fire Bricks designed for high-temperature industrial applications such as boilers, furnaces, kilns, chimneys, and steel/cement industries. Manufactured using premium fire clay and alumina for maximum strength and heat resistance.

Our Refractory Fire Bricks are manufactured using premium-grade fire clay and high alumina material to withstand extremely high temperatures in industrial environments. These bricks offer exceptional thermal insulation, high mechanical strength, low porosity, and excellent resistance to chemical corrosion.

They are widely used in boilers, furnaces, hot air chambers, kilns, incinerators, power plants, steel plants, cement industries, and refineries.

Available in multiple alumina grades (30%70%) and sizes according to customer requirements.

Each brick is tested for thermal shock resistance, compression strength, and dimensional accuracy, ensuring long service life and stable performance in high-heat zones.

| Specification | Details |

|---|---|

| Material | Fire Clay / High Alumina |

| Alumina Content | 30%, 40%, 50%, 60%, 70% (Available) |

| Density | 2.02.3 g/cm |

| Temperature Resistance | 1200C 1700C (Grade-wise) |

| Cold Crushing Strength (CCS) | 150350 kg/cm |

| Porosity | 1824% |

| Thermal Shock Resistance | Excellent |

| Brick Size | 230 115 75 mm (Standard) / Custom |

| Usage | Boilers, Furnaces, Kilns, Chimneys, Incinerators |

| Country of Origin | India |

High-temperature resistance up to 1700C

Premium fire clay & alumina construction

Excellent thermal and mechanical strength

Low porosity for maximum heat efficiency

Suitable for all industrial furnace applications

Available in standard & custom sizes

Long-lasting and cost-effective

32 85 per brick (Grade & alumina % ke according)

Price on Request

Minimum Order Quantity: 5001000 Bricks

Delivery Time: 17 Days (Stock-based)

Packaging: Pallet / Gunny Bags / Custom

Payment Terms: Advance / Online Transfer